Feb 17, 2023 Update

Executive Summary

Details

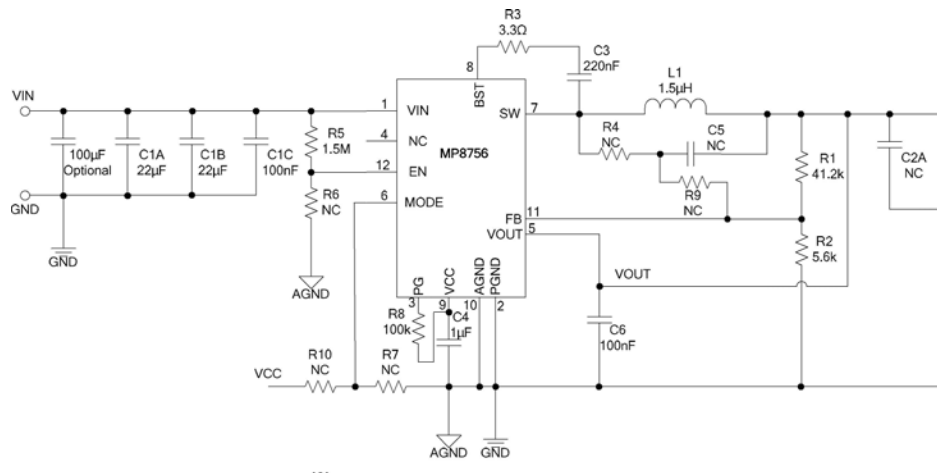

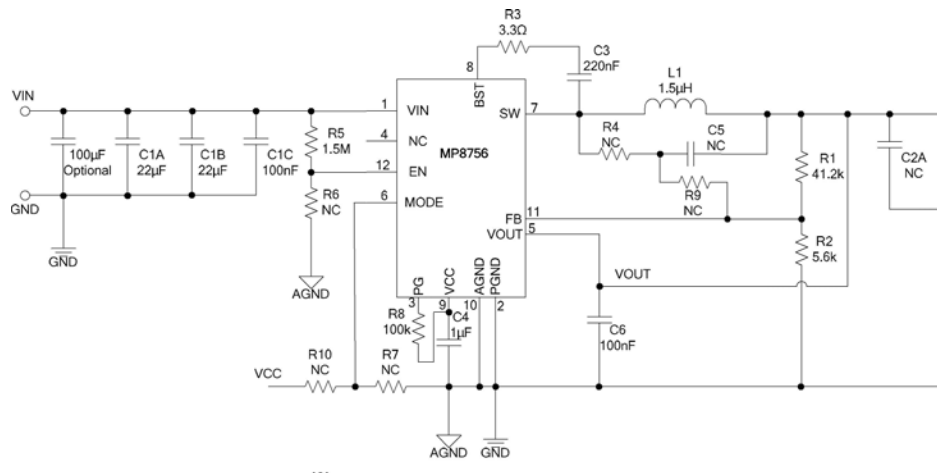

To make sure we didn't have problems below is are some rough design calculations per the sometimes correct datasheet.

import Text.Printf

-- We don't want to blow up the chip

-- so compute vEN to be sure that

-- 4.0 > vEN > 1.4

vIn = 12

r6 = 300e3

pullDown = 600e3

rp = (r6 * pullDown) / (r6 + pullDown)

vEN = (vIn * rp) / (1.5e6 + 600)

printf "vEN at 12V -> %5.2f" vEN

printf "vEN at 24V -> %5.2f" (2*vEN)

vEN at 12V -> 1.60

vEN at 24V -> 3.20

r6 at 300k yields a good vEN for 12 and 24v

vRef = 600e-3

r1 = 41.2e3

-- Calculate R2 for output volage of 5V

r2 = (vRef * r1) / (5.0 - 0.6)

printf "r2 = %5.2f" r2

r2 = 5618.18

Board values for FB resistors are correct for Vout is 5v.

vPG = 0.4 -- at I = 4ma

vCC = 3.6 -- nominal

Inductor Choice

fSW = 700e3

deltaI = 2.8 -- 30% of output current

vOut = 5.0

vIn = 12.0

indL = (vOut/(fSW*deltaI)) * (1.0-(vOut/vIn))

printf "L -> %5.2e" indL

L -> 1.49e-6

This means that the ripple current will be 2.8 amps

Peak Inductor Current

iOut = 6.0

iPeak = iOut + (vOut / (2.0 * fSW * indL)) * (1.0 - (vOut / vIn))

printf "Ipeak -> %5.2e" iPeak

putStrLn "This is below the max switch current of 10A"

Ipeak -> 7.40e0

This is below the max switch current of 10A

Power Good Circuit

The VCC output is 3.6 volts and the $V_f$ of the LED is 1.8V so the series resistor should be approximatly,

rLED = (3.6 - 1.8 - 0.4) / 4e-3

printf "LED series resistor -> %5.2f" rLED

putStrLn "So make it 330 for about 4ma"

LED series resistor -> 350.00

So make it 330 for about 4ma

Talked with Joey.